ERP system, which is used at Sa-ba in material purchase planning and raw material procurement, is supported with barcode application and the system is ensured to work concurrently and without failures, customers' and suppliers' orders are tracked on the internet via EDI system.

The goal is to meet customers' needs exactly on time, plan purchase of materials in the long run correctly, and to procure raw material needs on time.

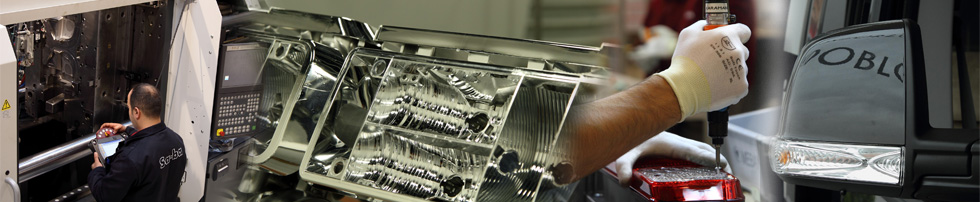

• Plastic Injection

There are 27 injection machines weighing 6-420 tons at Sa-ba. OEE (Overall Equipment Effectiveness) data are tracked on a daily basis; the development and gain achieved within the enterprise through daily 5S and TPM inspections are shared with customers systematically.

• Metallization

Sa-ba's metallization process is capable of meeting OEM expectations at every scale. Maintenance and overall equipment effectiveness are under close follow-up.

• Assembly

Assembly lines at Sa-ba have been designed for interior and exterior lighting systems of automotive sector, and have been developed in a way that they will meet high quality and efficiency expectations. Poka-Yoke systems, daily OEM analyses, 5S inspections and kanban applications are continuously developed.

• Vibratory and Ultrasonic Plastic Welding Processes

There are six ultrasonic welding machines and four vibratory welding machines at Sa-ba. The vibratory machines operate with six axis robots. Measurement stability of lower plastic parts is under the control of SPC system, vibratory welding process is of computer, and dies are under control via pre-centering operation. All parts have been equipped with PLC and poka yoke systems, and undergo hundred percent sealing checks.

• PUR Seal Unit

The six-axis robot supported system which can seal casting on surfaces of every geometry is capable of conducting the most sensitive applications. Raw materials are determined in accordance with customer needs at the stage of designing; product life and quality are guaZodiaceed.

• Hardcoating Unit

5-15 micron thick transparent hardcoating, which increases UV resistance for durability against fading and scratching, is done under spray system on continuously flowing production line, under positive ambient pressure at Sa-ba; and coating thickness is measured with Carl Zeiss equipment, its quality is ensured.sistemli sürekli akar üretim hattında, pozitif ortam basıncı altında yapılmaktadır ve kaplama kalınlığı Carl Zeiss ekipmanlarıyla ölçülmekte, kalitesi gaZodiaci altına alınmaktadır.

• Electronic Circuit Plant

All of the electronic circuits designed by Sa-ba according to the requirements of customers and regulation are produced in ESD environment; solder quality, PCB card placement correctness and functional features are controlled via optical cameras and control jigs.